Laser Workstations for Medical Manufacturing

Unparalleled cut speed, precision and accuracy.

WHATS NEW

Alpine Laser Articles and Insights

A few recent articles and videos featuring Alpine Laser and our Laser Workstations

Medical Manufacturing

Hyper-Focused Design for Medical Device Manufacturing

As former Medical Device Professionals, we understand the rigorous requirements of the Industry. Like many of our current customers, we found ourselves searching the market for that perfect system. A machine that was built for the medical manufacturing niche, a system flexible enough to support quick part change-overs, but robust enough to withstand the demands of long term production. A machine easy enough for a technician to operate, yet powerful enough to enable a power user to develop and create parts that were not previously possible. Simply put, there were no commercially available solutions did not require immediate rework or customization. This is how the Medicut PRO Series Laser Workstation platform was born, a highly configurable standard platform piece of engineering, designed for you...the medical manufacturer.

Standard Platforms

Configurable Standard Platforms allow for late stage customization while reducing customer lead times and providing the flexibility customers need. Standard options and stocked inventory allow for reduced lead times and increased flexibility while maintaining high-quality results.

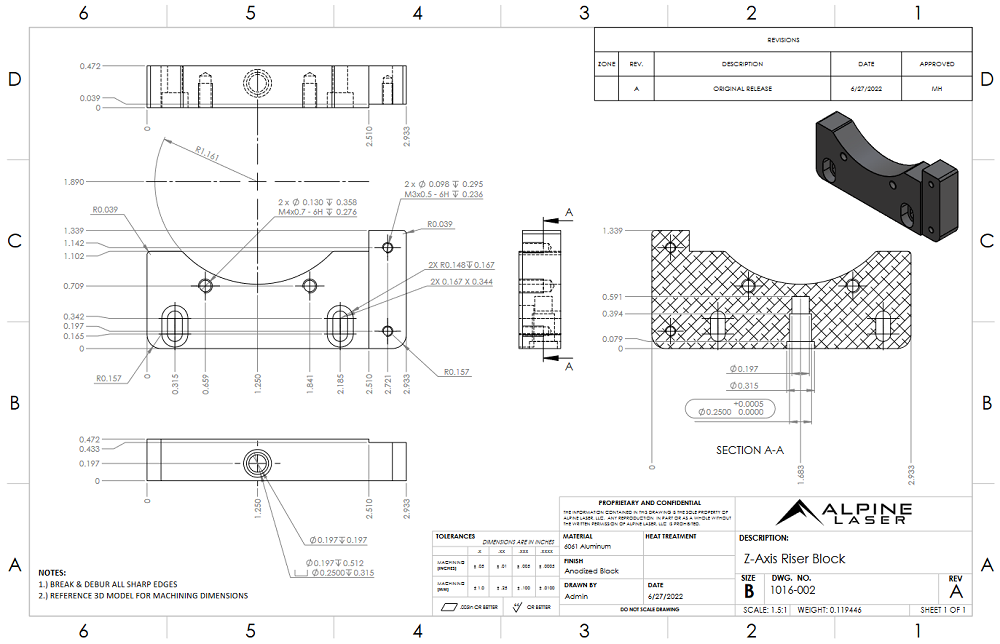

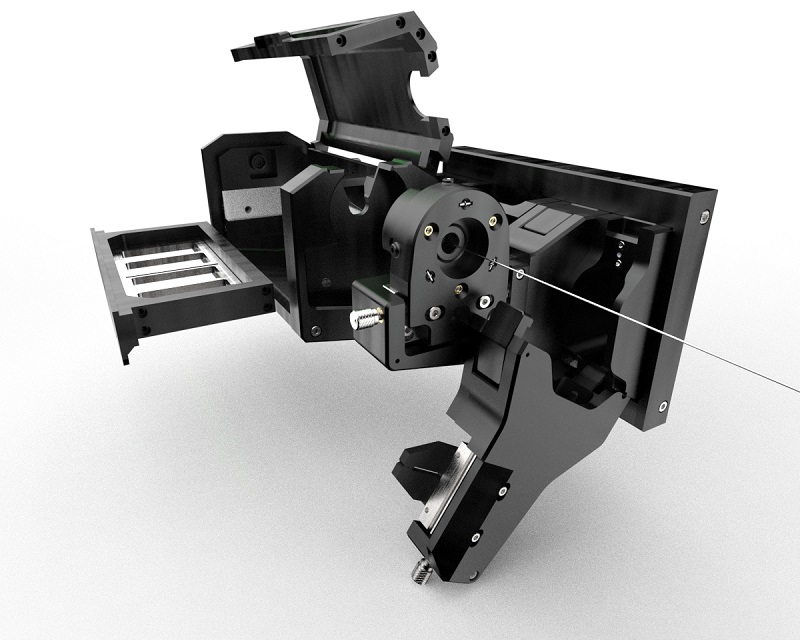

Modular Tooling

Modular Tooling with 5-Axis fine adjustment, flexible enough for rapid prototyping, robust enough for high-volume production. Part change-over in as little as 2-3 minutes. Its ease of use and adaptability ensures optimized production efficiency.

Safey & Compliance

Safety & Compliance is a critical aspect of our Laser Workstations. Our systems are meticulously designed to meet and exceed all regulatory requirements and safety standards, featuring Class I CDRH Compliance and Category III Safety Controls.

Service & Scalability

Fully serviceable from the front and two sides. Custom Side-Access sliding Electrical Cabinet allows back to back operation without the need to service or access rear of machine. Scalable design in a minimal footprint ensures maximum equipment production output for your medical device manufacturing space.

Medicut PRO Series

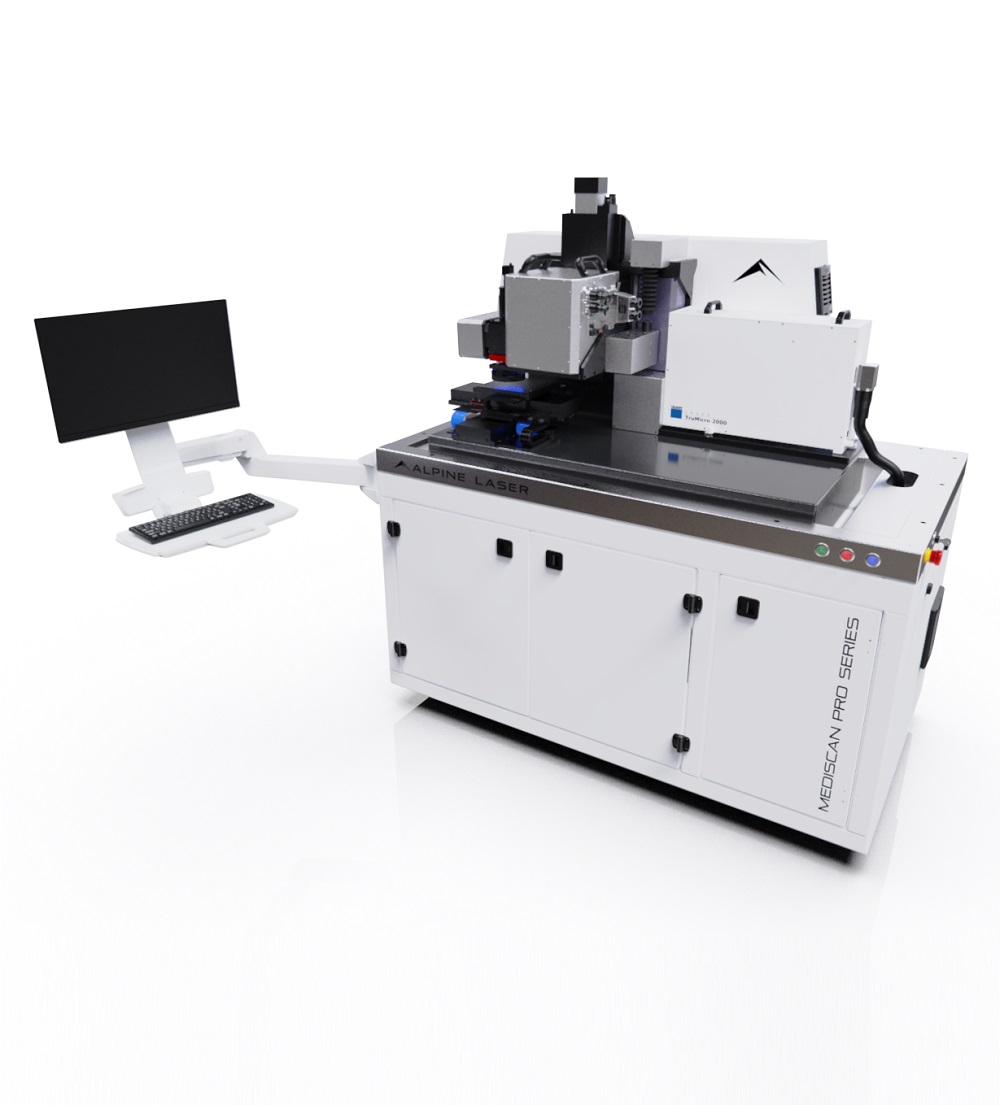

Medicut PRO Series Laser Workstations

Alpine Laser Medicut Pro Series Laser Systems are configurable multi-axis workstations for small diameter tubular and flat sheet medical components. Available in CW pulsed-fiber, femtosecond and fiber-delivered femtosecond laser configurations

CLICK on Left Menu Buttons below to view a brief summary of each product platform

Medicut PRO Series

Standard Platforms, Configurable for Medical Manufacturers

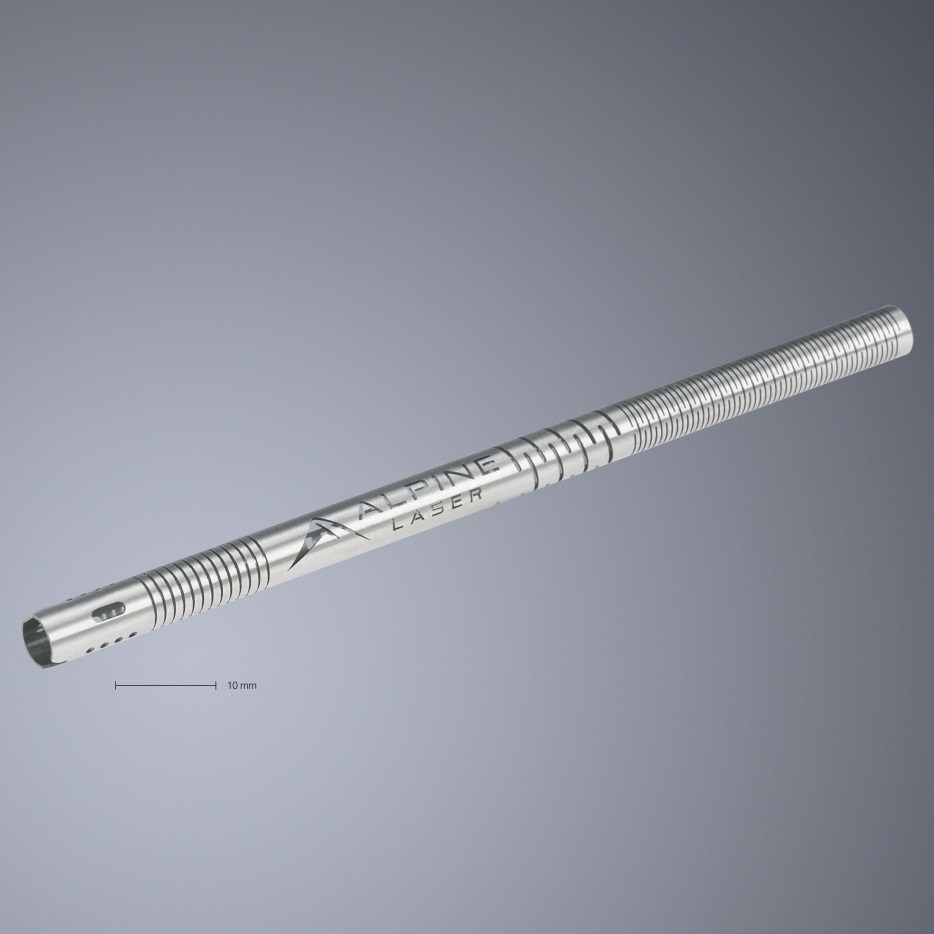

Fiber Laser Systems

The Alpine Laser Medicut PRO Series Fiber Laser Workstation is our Flagship product which offers high precision and speed. This modular platform features a wide variety of standard options, is highly configurable, and a modular tooling array that includes fine adjust features to allow for rapid part change-overs. The ultra-compact form factor is less than 48 inches wide, making it a space-saving option for any workspace.

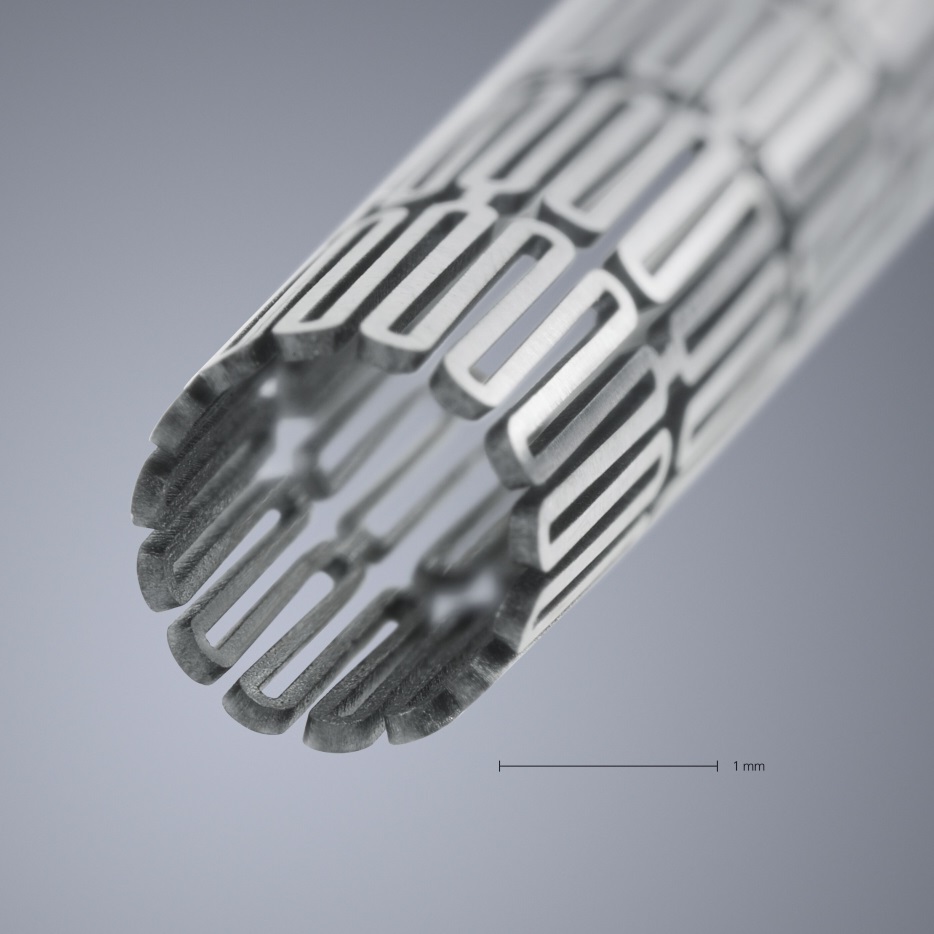

Fine Kerf Widths down to sub 0.001"

Laser Control Interface

Ultra-Compact Footprint

High-speed Dyanamic Profiling

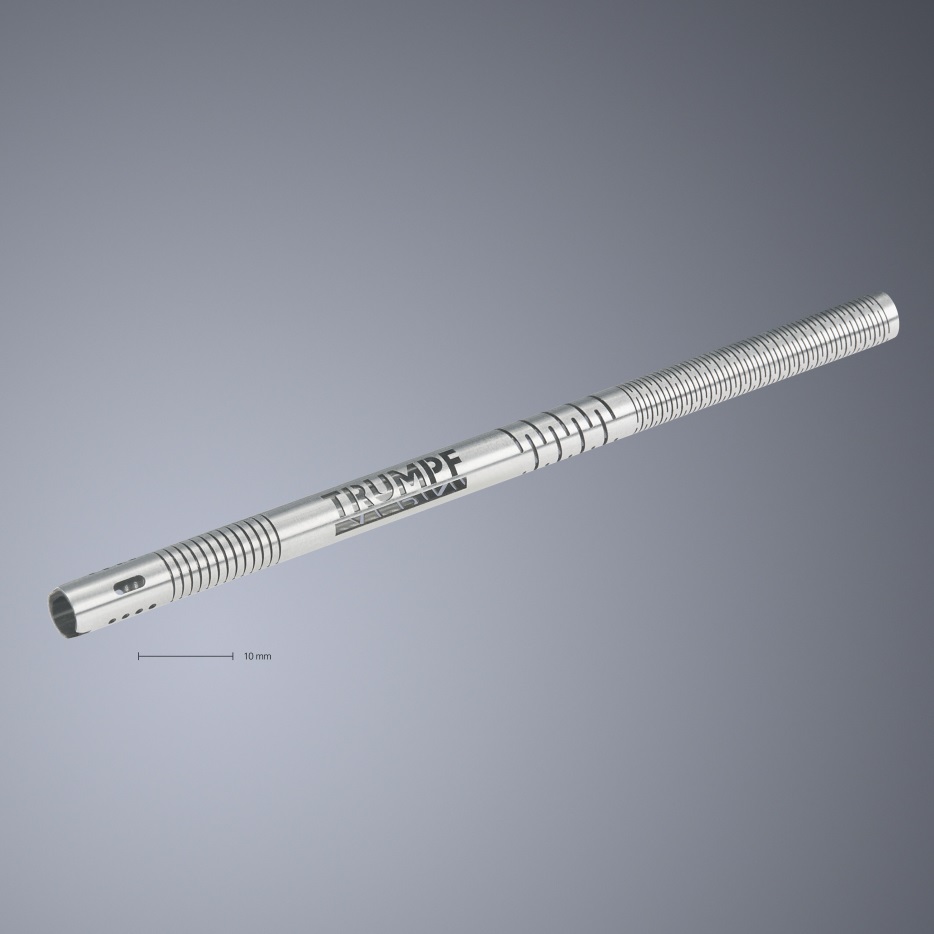

Femtosecond Laser Systems

Our Femtosecond Laser workstation features TRUMPF's TruMicro 2030 paired with a hollow-core-fiber beam delivery system to enable a high-performance, ultra-compact femtosecond laser solution. The Hollow Core Fiber-Delivery system allows us to position the power source inside the workstation base and features a flexible connection between the processing head and the laser source, enabling a high performance package and ultra compact space saving form factor unlike anything else on the market today.

Fiber-Delivered Femtosecond Lasers

Laser Features

Kerf widths down to 0.0004"

Automated Loading & Unloading Available

Galvo Laser Systems

3-4 Axis Motion Platform coupled with a 5-Axis Galvo head allows for advanced femtosecond laser micro processing and drilling of flexible geometries including laser cutting and structuring. Additional Configurations available upon request...

Precision Micro-drilling applications

Allows for Laser Processing Complex Geometries

Intuitive Software with GUI to easily create simple or complex toolpaths

Suitable for a Variety of Laser Applications

Flat Sheet Laser Systems

Alpine Laser offers a standard workstation with a full 200mm x 200mm XY Cutting Envelope. Workstations can be equipped with optional Rotary Axis and tilt heads. Available in both fiber and femtosecond laser upgrades

Fiber or Femtosecond Lasers

XY Cutting Envelop of 200x200mm

Standard or Galvo Beam Delivery Options

3-5 Axis Flat cutting with Rotary and Tilt Head Optiosn

Precision Engineering

Differentiated Technology

2-5X FASTER

Advanced Motion Control

• Control architecture allows for ultra-high speed synchronization

• Enables unparalleled cut speed, precision and accuracy

High Dynamic Acceleration Profiles

• Allow for moving through intricate and sharp geometry quickly

• Rotary options for peak velocities up to 3,000 RPM

Full Modular Tooling Array

• All tooling hardware built with 3-5axis of fine adjust with locking

• Part and Tooling change-overs in as little as 2-3 min

• Precision Regrip Module, m-code controlled regrip to less than 0.0005" positional error

Applications Lab

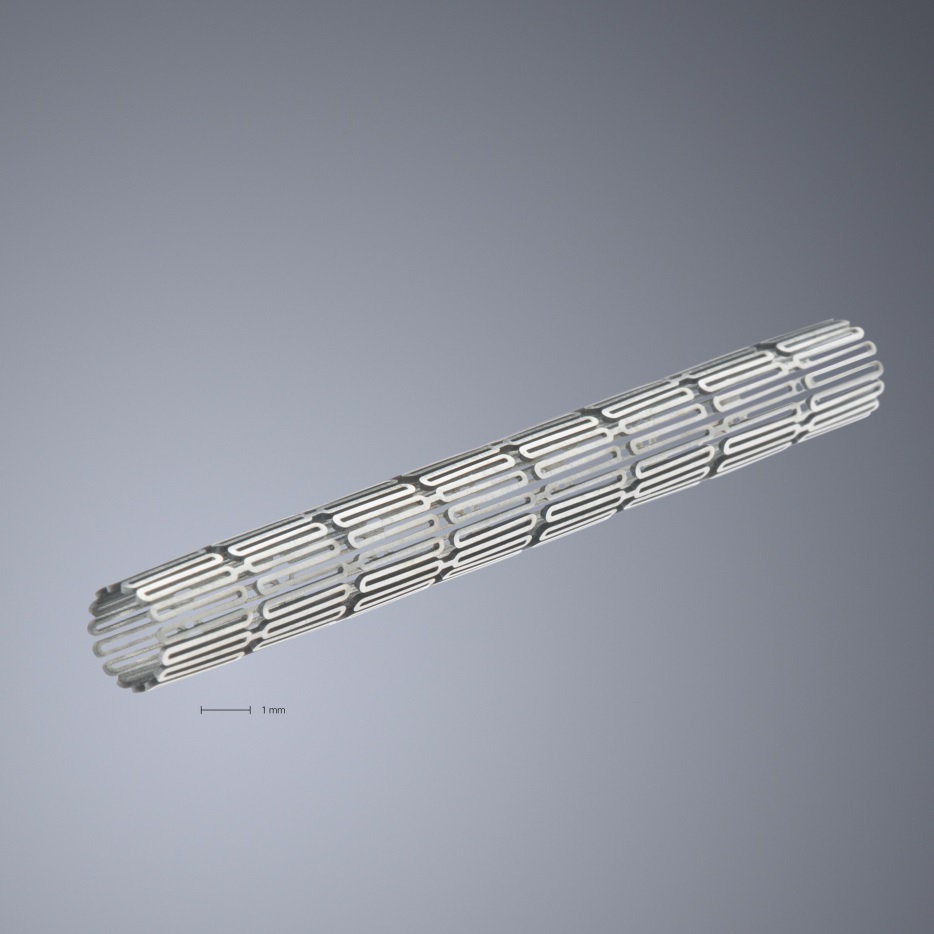

Laser Cut Samples & Process Development

Medicut PRO Series Laser Workstations are capable of producing burr free, high precision medical components. Our systems are known for their performance and constantly outperforming legacy equipment on the market. With an average cycle time improvement of 2-5X, our laser workstations not only enhance productivity but also deliver improved cut quality and profiling.

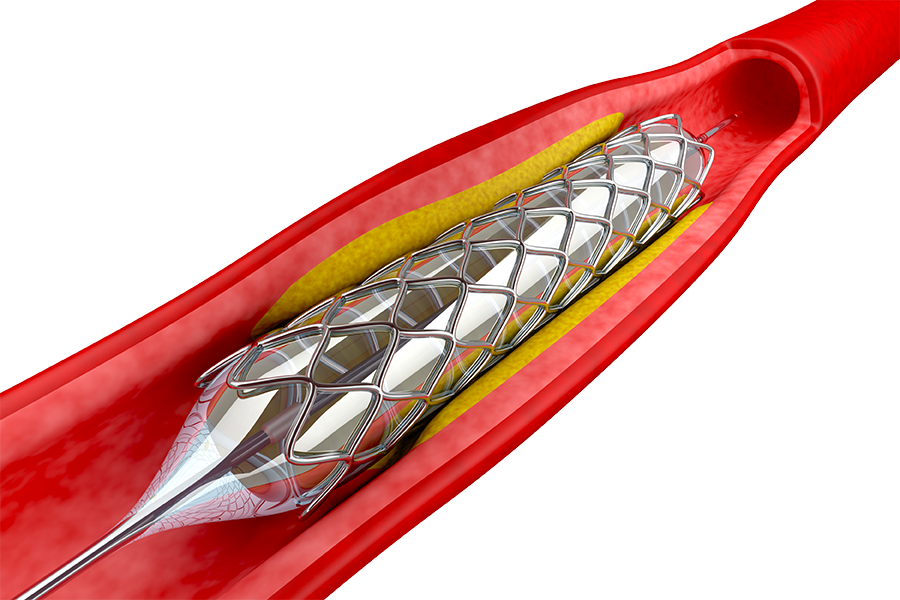

Laser Processing Equipment Critical to the Growth of Several Technology Markets

Rapid growth in demand of laser-based medical devices and components, enabling healthcare providers to provide patients with advanced treatments, while driving innovation and improving patient outcomes. Below are just a handful of the many technology markets serviced by Laser Processing Equipment.

Cardiovascular

Dental

Diabetes

Electrophysiology

Minimally Invasive Surgery

Neuromodulation

Ophthalmology

Orthopedic

Peripheral Vascular

Sports Medicine / Trauma

Structural Heart

Urology

Therapeutic End Markets

Technology Markets serviced by Laser Processing Equipment

Laser processing technology plays a vital role in the medical technology markets, facilitating the production of high-precision medical devices, implants, and surgical instruments. It enables efficient cutting, welding, marking, and surface modification of materials used in the medical industry

Device Design

Medical Applications

Our laser technology facilitates the production of precise and customized medical devices, implants, and instruments used in a wide range of medical applications, resulting in improved patient outcomes. Laser processing technology is driving growth in medical device production, allowing for intricate designs and precise cuts that enhance treatment efficacy and enable minimally invasive procedures

Laser Processing Equipment used in the Design & Development of Various Medical Applications

Ablation Catheters

Flex & Structural Members

Interventional Cardiology

Microcatheter Shafts

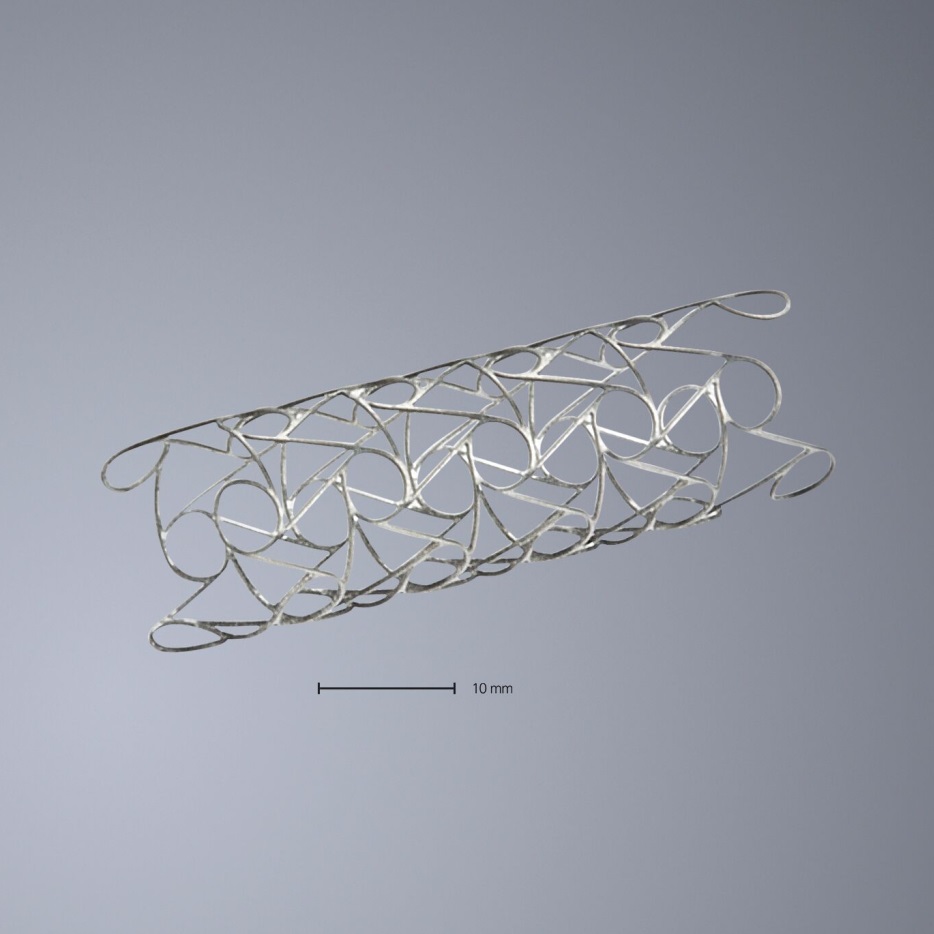

Nitinol Stents

Pull Rings

Retrieval Devices

Steerable Delivery Catheters

Stent & Tubular Components

Structural Heart

Vessel Closure Devices

FAQ

Commonly Asked Questions

Have a question? Here are some commonly asked questions. Prefer to set up a call to discuss your application in detail? Feel free to Contact Us

We prioritize providing our customers with the optimal solution for their needs, rather than upselling on unnecessary features. Our engineers are available to consult with you regarding your specific application requirements. At Alpine, we offer a variety of motion packages and options to meet your needs. It is crucial to choose the right package for your application, as overloading a machine with unnecessary options can limit its dynamic performance. Opting for a machine that fits 95% of your requirements instead of 100% can actually result in higher ROI and cycle times.

Our product family offers highly-engineered machine base platforms with configurable standard options that enable us to stock ~90% of the components required to build your machine. Unlike the typical industry lead times, which can approach one year, our current lead times are significantly better than our competitors'. We are continuously working to improve our inventory measures to achieve our goal of shipping a machine in under 12 weeks

We have conducted extensive benchmarking on customer parts using our platform against every commercially available machine, comparing as-cut quality to existing processes and cycle times. Our results have been unparalleled thus far. We typically achieve 2-5X cycle time improvement while maintaining or enhancing cut quality. Many customers are surprised to learn that their current machines from leading manufacturers are not operating at their commanded feed rates. Implementing our easy-to-use, modular quick change tooling platform and choosing the correct system configuration can result in fast ROI and significant increases in manufacturing output. Our high customer retention rate attests to the outstanding performance of our systems

Our purpose-built medical manufacturing laser platform is designed with pre-configured standard options that are carefully engineered to minimize the need for staffing large teams of engineers, technicians, and admins. Our operational efficiency sets us apart from competitors, particularly large corporations that can be slow and inefficient due to chains of approvals and corporate bloat. Our efficient operating process and low overhead enable us to offer cutting-edge technology at competitive prices. We pride ourselves on our ability to quickly adapt to new technologies and to listen to the voice of our customers