Medicut Pro Series Feature Overview

Read more below about our modular standard platform, included features and configurable options...

Designed for Medical Manufacturers

Medicut PRO Series Features & Options

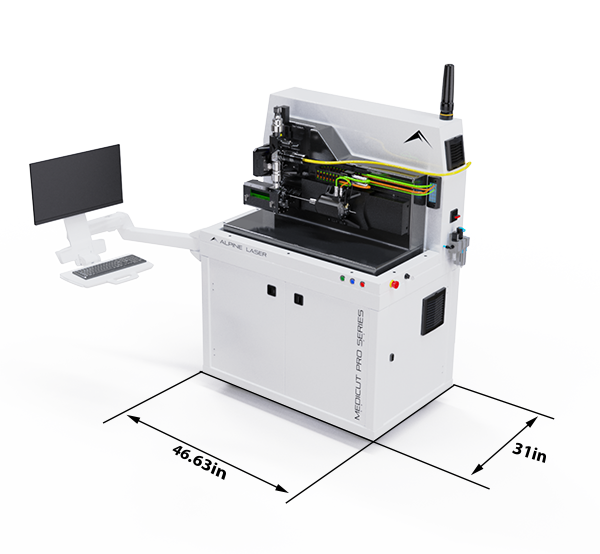

The Alpine Laser Medicut PRO Series Femtosecond Laser Workstation combines the precision of femtosecond laser processing with our high performing, modular platform for tube cutting. The end result is a system featuring High Precision, High Speed, Configurable standard options on a highly modular base platform. All integrated into an ultra compact footprint of less than 48 inches wide.

Featuring an Ultra-Compact Footprint

Medicut Pro Series Laser Workstations are the smallest tube cutting systems on the market. With a footprint of just under 48in x 31in, they are easily integrated into existing manufacturing spaces. The standard workstation is offered in a convertible configuration. CDRH compliant safety and interlocks moved to the compact cutting enclosure frees up and allows operators the flexibility to operate.

Safety & Compliance

Our Laser Workstations have been meticulously crafted to ensure safe operation, equipped with hardware that complies with Class I CDRH standards and Category III Safety controls. Each system is outfitted with reliable safety interlock devices, laser safety glass, and easily accessible E-stop controls. Our workstations also come equipped with advanced Fault Detection and active monitoring features, as well as redundant safety circuits for all safety devices, ensuring maximum safety for users.

Founder & Commercial Leader at Alpine Laser

Standard Option

200W Fiber

Our Medicut PRO Series Fiber lasers come equipped standard with the 200W Air-cooled Trumpf TruFiber P compact Fiber Laser. Available with 50mm or 80mm focus lens. Our standard spot size is around 25 micron (0.001inch)

Optional Upgrade

Fiber Laser Options

Additional Fiber Laser options available include the lower power 100W TruFiber P Compact Laser, as well upgrades to 300W and 500W Fiber Lasers. All fiber laser options are 100% compatible with Alpine Lasers custom Laser Interface.

Optional Upgrade

Femtosecond Upgades

-Trumpf TruMicro Ultrafast (10W, 20W, 100W)

Available with Optional Hollow Core Fiber Delivery

-Light Conversion Carbide CB3 (20W, 40W, 80W, 120W)

-Light Conversion Carbide CB5 (5W, 6W) Air-cooled

Standard Feature

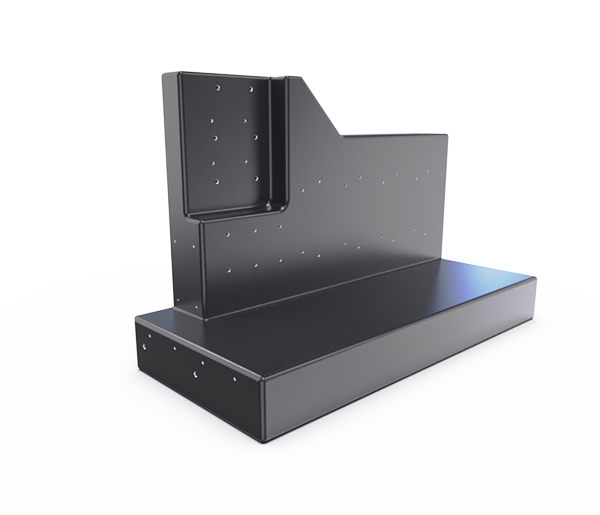

Mineral Cast Epoxy Base

Engineered for Maximum performance, Designed for every configuration, Stocked in Inventory

Designed for Configurability

Our engineered bases are designed with over 60 over molded threaded inserts which allow for 100% configuration across our product platform. This allows us to keep bases on hand in inventory and cut lead-times.

Vibration Damping

Engineered Bases are formulated from a blend of silicon dioxide ceramic quartz aggregate and proprietary additives. Our bases feature 14.5X Vibration Dampening Performance improvements over that of natural stone granite.

Engineered for Longevity

Castings are designed to outlast the life of the machine. High compressive strength, improved thermal stability, zero moisture absorption rates, high vibration isolation, dimensional stability.

Standard Feature

Modular Tooling w/ Compact Cutting Enclosure

Our Modular Tooling Platform streamlines the tool change process for laser tube cutting. Change tooling/tube sizes and be up and cutting in as little as 2 minutes. Each tooling slice can be independently removed and swapped with various options. These tooling options can be purchased at the time of the workstation order, purchased at a later date, or swapped between machines on your floor.

5-Axis Fine Adjust

5 full axes of precision control at your fingertips via fine adjustment screws. X,Y,Z and full Tip Tilt ensure your tube is always aligned precisely where you need it.

Precision Regrip

Execute precision automated regrip operations via our M-code controlled positioner. Precisely execute regrips with less than 0.0005" positional error. Typical Regrip times are performed in under 1 second

Quick Change-Over

The worlds first true standardized modular tooling platform tailored for the Medical Device Industry. Change over tube sizes in 2-3 minutes.

Part Holding

Precision bushings, adjustable v-block guides and micro tube handling, we offer options to cover your needs in addition to offering a threaded array for customer specific fixturing

Standard Feature

Custom Alpine Laser Interface

We've designed a custom Ethernet application to harness the full remote power of our fiber laser.

G01 X0.3659 Y3.8911

M98 P102

G01 X0 Y7.7823

M98 P102

G01 X0.2241 Y4.0912

M98 P103

ProcessGasOFF

ProcessGasSelect=1 //Change to Oxygen

ProcessGas_Pressure=125 //Set Pressure

ProcessGasON

LaserPower=10 //Change Laser Power

LaserPulseWidth=60 //Change Pulse Width

G01 X0.8978 Y0.7597

M98 P101

G01 X0 Y1.8837

M98 P101

G01 X0 Y3.5172

M98 P101

G01 X0 Y1.8836

M98 P101

LaserMode=3 // Switch Laser Modes for Helical Profile

LaserPower=25 // [%]

LaserFrequency=7.5 // [kHZ]

LaserPulseWidth=90 // [µsec]

FR_Cutting=90 // mm/s

G01 X0 Y1.8837

M98 P111 //Goto Helical Subroutine

M30

Motion Program Control

FULL program control of Laser Power, Pulse Width, Frequency, Ramp Up, Ramp Down, Timed/Shot Modes, etc.. Change parameters on-the-fly using M-code or word based programming via Custom Alpine Laser Interface.

Laser Modes

Our systems are configured with 3 laser modes. Capable of cutting both complex high density features and high-speed interrupted helical profiling. Laser modes can be changed on demand. Helical Mode is not only designed special for on-the-fly laser processing, but also removes the 'short starts' companies commonly fight with.

Pulse Shaping

Graphical Programming interface allows for the easy creation of any pulse shape. Ability to save up to 50 user-defined pulse shapes. Pulse shapes can be produced with up to 1000 individual segments with a resolution of 1μs per segment.

Standard Feature

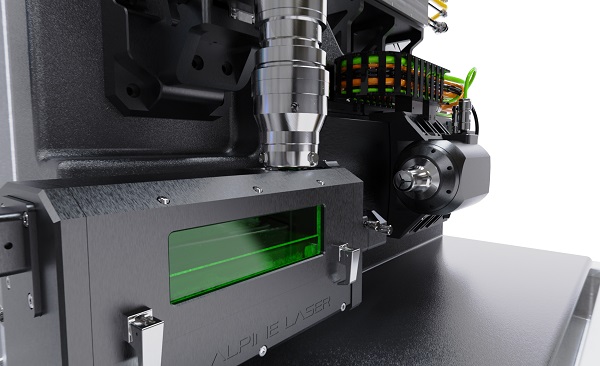

Integrated Closed-Loop Wetcut

Closed Loop, Integrated Wet Cut availble with full water level monitoring, Standard O-ring style water jackets as well as pressure controlled waterjacket upgrades improve process repeatability

Standard Feature

Integrated Closed-Loop Wet Cut

Closed Loop, Integrated Wet Cut availble with full water level monitoring, Standard O-ring style water jackets as well as pressure controlled waterjacket upgrades improve process repeatability

Active Filtration

Level Monitoring

Manual Quick Clamp

Programmable Water Jacket

Standard Feature

Quick-Clamp Water Jacket Mount

Closed Loop, Integrated Wet Cut availble with full water level monitoring, Standard O-ring style water jackets as well as pressure controlled waterjacket upgrades improve process repeatability

Standard Feature

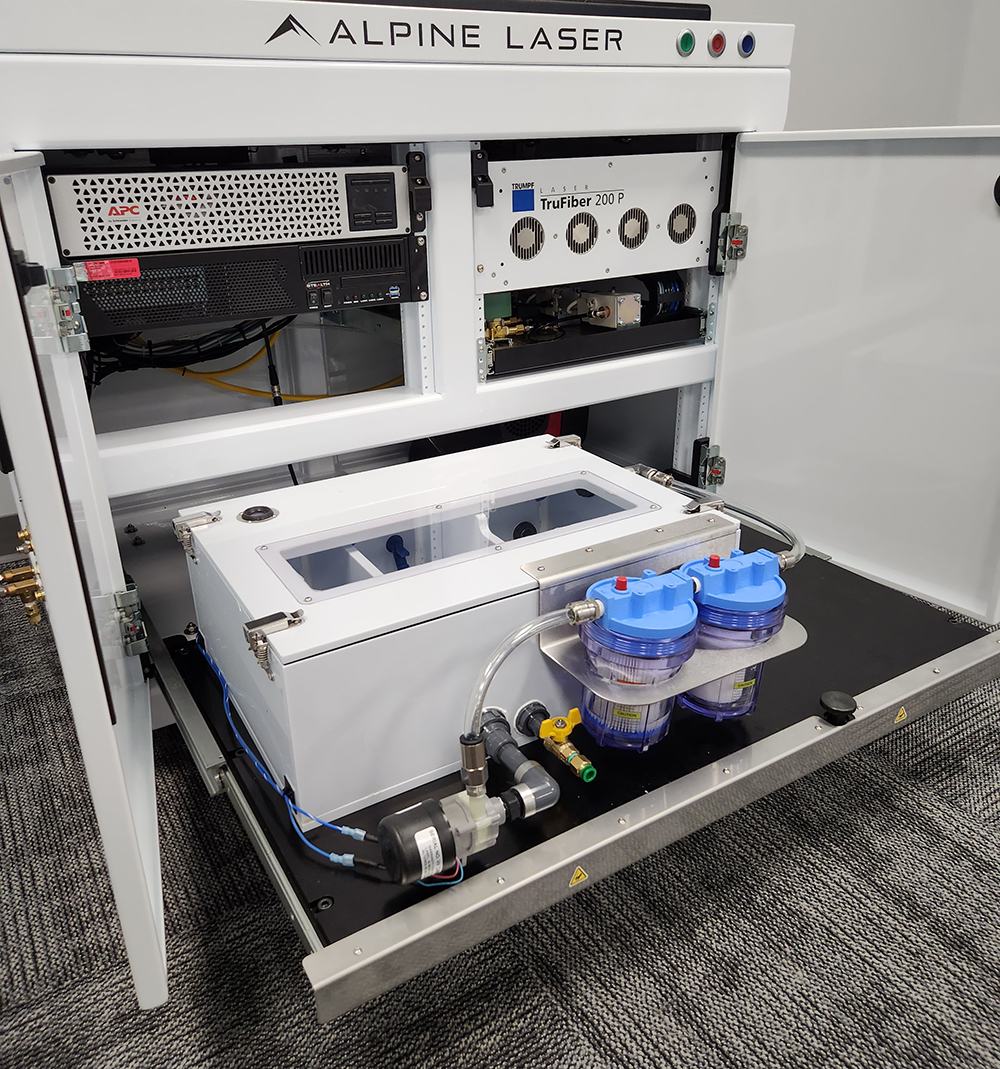

Front & Side Access Servicable

Fully serviceable from the front and two sides. Custom Side-Access sliding Electrical Cabinet allows back to back operation without the need to service or access rear of machine. Scalable design in a minimal footprint ensures maximum equipment production output for your medical device manufacturing space

Image 1

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore aliqua.

Image 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore aliqua.

Image 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore aliqua.

Compare our Standard Motion Packages

Feature

Tube Diameter

HMI Pressure Controlled Rotary Collet

Rotary - Max Speed

Max Operating Velocity [RPMs]

Rotary - Dynamic Acceleration

Programmable Pressure Controlled Collet

Wet Cut Compatible

Rotarys are designed with full through-bore solid spindles

X-Axis - Max Length

X-Axis - Max Speed

Please contact an Alpine Laser Representative if you have additional questions or would like to review additional hardware specifications

Medicut Pro Optional Features

Below is a non-comprehensive list, featuring a few options that available for quoting by request